Iridium vs platinum vs cooper spark plugs

A car can't be started without spark plugs. The purpose of this part is to convert the voltage from the ignition coil into a spark, thus igniting a mixture of fuel and air. The efficiency and performance of the engine depends directly on how efficiently the spark works. An ignition failure causes the entire air-fuel mixture not burned out in the cylinder is transferred to the exhaust system. And combustion of fuel in the catalyst is extremely undesirable, it can be broken down.

When it's high time to replace the spark plugs in your car, you're likely to come across a wide range of choices. You will see at least four different types of spark plugs from at least three different manufacturers. Will it be platinum spark plugs? Copper spark plugs? Iridium spark plugs? How do you know what the best spark plugs are? In this article we will explain the difference between platinum spark plugs, copper spark plugs, iridium spark plugs and others.

Variety of spark plugs

Nowadays a large number of various spark plugs are produced. Here are the main features by which the types of spark plugs are distinguished:

- number of electrodes - with one negative electrode (simple) or multielectrode;

- the material which the central electrode is made of - yttrium, tungsten, platinum, iridium, palladium;

- heat range - "cold" type or "hot" type.

A typical product is a standard version with one central electrode and one side electrode. The spark in such an element constantly slips between these electrodes, which leads to a relatively rapid burnout. It is important to know that the manufacturers did not limit themselves to just increasing the number of electrodes. At the same time, different materials are used to produce them. It turns out that most of the main characteristics of these elements will depend solely on the peculiarities of the electrode part production. In other words, the thing, which matters is the material of the electrode or its tip.

For this reason, it is commonly accepted to distinguish the spark plugs as:

- copper or nickel chromium spark plugs;

- platinum spark plugs;

- iridium spark plugs;

This means that either cheaper material (e.g. chromium and nickel) was used during electrode production, or an expensive rare-earth metals (platinum, iridium) was used. The final cost of the product also depends on this factor.

The history of spark plugs made of precious metals

Spark plugs with electrodes made of precious metals, especially when considering mass applications appeared relatively not so long time ago. Previously, car manufacturers had been satisfied with nickel or chromium-nickel electrode spark plugs. So what was the initial reason to produce more expensive spark plugs? What advantages do they really have?

For decades, a priority in the design of internal combustion engines for passenger cars was focus on their reliability, relative simplicity and maintainability. Therefore, the spark plugs were arranged in such a way that the motorist could change them quickly with the appropriate key. However, by the 80s of the last century the trend changed. The market required more power, even though the energy crisis was more and more on the rise..

There were two main trends in motor engineering that were directly related to spark plugs.

Firstly, in order to increase the efficiency of the engines and save bonnet space, the engines were becoming more compact. As a result, spark plugs were sometimes installed in hard-to-reach places. This means that the procedure for replacing spark plugs was becoming more expensive and, consequently, there was an urgent need to extend the service interval.

Secondly, the constant rise in fuel prices and environmental requirements forced more and more horsepower to be squeezed out of a litre of tractive volume. These engines required increasingly cold spark plugs, i.e. those that are less heated during the engine operation to avoid ignition of the glow plugs. However, these spark plugs last longer and are heated to a self-cleaning temperature (750-900°F), so they are more susceptible to soot formation. In addition, it was necessary to look for materials with higher erosion resistance level than chromium nickel metals, because at operating temperatures in such motors, the destruction of conventional electrodes, accompanied by an increase in the spark span, occurs faster.

Generally speaking, the solution, which allowed to increase the chemical stability of spark plug electrodes, what’s more, in a dramatic way (so as to significantly increase the replacement interval), was obvious. It was necessary to use refractory and chemically inert material.

As it was already mentioned above, the first precious material that spark plug manufacturers paid attention to was platinum - refractory and durable metal. Pure platinum is resistant to corrosion, but does not have the necessary hardness. Unique additives solved this problem without reducing corrosion resistance.

The only drawback of platinum spark plugs, especially at that time, was the high price. Even with their long service life, they were more expensive to buy than a few sets of ordinary spark plugs, which were used during the same mileage. The economic effect could be visible only on engines, where the procedure of replacing spark plugs took a long time, as the cost of a standard operating hour of a qualified mechanic in developed countries is very high. Therefore, all the time they were looking for an alternative material. Surprisingly, the choice was made for iridium - metal is even more unique than platinum.

Although iridium is a rarer metal, its pricing depends on market volatility. Currently, its price is still cheaper than that of platinum, and almost one fifth of the world's iridium production is now spent on spark plugs. Iridium is an extremely hard metal element, almost an order of magnitude harder and stronger than platinum. In addition, the main feature that makes iridium attractive as an electrode material for ignition systems is its extremely high melting point of almost 4500°F (see table).

| Material | Melting point (ºF) | Hardness (Hv) | Strength (kg/mm²) |

|---|---|---|---|

| iridium | 4442 | 450 | 110 |

| platinum | 3218 | 50 | 15 |

| nikel | 2642 | 160 | 70 |

They didn't manage to use pure iridium, so a special alloy was created. Various additives to iridium were tried, and eventually stopped at the element of rhodium. This is a very rare and highly scattered element in nature. Luckily, and it does not require much - DENSO engineers have reached a ratio of iridium/rhodium equal to 9:1 (90% iridium and 10% rhodium).

As for platinum, despite the use of iridium, it did not give up its position in the production of spark plugs. As the maintenance has shown, it is necessary to protect not only the central, but also the side electrode for the maximum service life of the spark plug.

If the central electrode is made of platinum or iridium, then the wear of the plug is only due to the burnout of the side electrode. In this case, the service life of the spark plug with central iridium electrode and side one made of nickel alloy is about 35 thousand miles, so the maximum service life could be achieved only when using precious metal on both electrodes. The fact that the wear of a standard spark plug is as follows: one unit of the span increase due to spark erosion of the central electrode, taken for 100%, is made for about 30% of the wear of the central electrode to 70% of the side one (a small range of these values is possible, depending on the design and applied nickel alloy). However, it is not profitable to use iridium on the side electrode, first of all, because the side electrode is less loaded with temperature and due to its properties of iridium it is very difficult to combine with other metals. And secondly, if DENSO uses high-temperature laser welding in the case of the central electrode, this is not cost-effective compared to the slightly thicker platinum electrode, which is less technologically difficult to mount.

This is how DENSO SIP technology, which evolved in DENSO Iridium TT, got used to it and went into mass.

Copper Spark Plugs

Copper spark plugs have a strong copper core, but the working end of the electrode- the centre in fact is 2.5 mm in diameter, it is a nickel alloy. Remember, the smaller the diameter is , the lower the voltage is required to start a spark. The nickel alloy is also softer than platinum or iridium, so the sharp edge firing you get right out of the box tends to wear out quickly. Despite these drawbacks, copper spark plugs are still a good choice for some engines. Copper spark plugs are better for old (up to 1980's) cars with low voltage distributor based on ignition systems. But don't use a copper high-energy spark plug supplier-less than a DIS or a coil-on-a-pinch (COP) spark plug. They wear out too quickly.

There is one exception to this advice. Late models of high-performance engines have been developed especially for copper spark plugs. In those cases, copper spark plugs are considered to have a high spark plug performance. If the manual demands to use copper spark plugs, do not use platinum or iridium spark plugs.

Platinum Spark Plugs

Platinum spark plug tip, mainly designed as copper one with a platinum disc welded to the central electrode tip. Since platinum is more difficult to destroy than nickel alloy, the shape of the electrode can be preserved up to 30-45 thousand miles of run. Platinum spark plugs are also slightly hotter, preventing fouling.

Platinum spark plugs are generally better suited for ignition systems of newer vehicles with an electronic ignition-based distributor and some other systems. If the user manual recommends platinum spark plugs, do not switch to copper spark plugs to save money. However, you can install either double platinum or iridium spark plugs.

Double Platinum Spark Plugs

Double platinum spark plugs were developed for the "spark waste" of direct ignition systems. In the Spark Waste System, spark jumps from the central electrode to the side electrode at the compression stroke. Return the electrical impulse back to the ignition coils package, the spark jumps back (side to side in the center) on the partner cylinder. Since the cylinder is being released by the partner on the release chute, the spark does not ignite . You cannot use a single platinum spark plug or traditional copper spark plugs in these systems because the side electrodes are not designed to handle the back-ignition. But the double platinum spark plugs with platinum disc welded to their side electrodes work exceptionally well. The center and side platinum discs remain sharp, allowing sparks to fly easily in both directions without causing rapid electrode wear.

If the user manual recommends a double platinum spark plug, it is the best one to be used. Never put other types of spark plugs in such engines. However, you can switch to the iridium/platinum joint connector (iridium center electrode with platinum tip side electrode).

At the compression stroke

Spark hits from the central electrode to the side electrode

Double platinum candles

Spark shoots from the side electrode on the central electrode

Iridium Spark Plugs

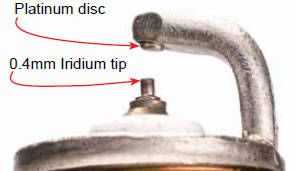

You must have guessed that iridium is harder than platinum. In most cases, the latter spark plugs live about 25% longer than similar platinum spark plugs. Since iridium is expensive, iridium spark plug manufacturers reduce the diameter of the central electrode to 0.4 mm. Besides saving money, the centre of the spark plug iridium electrode for thin wire increases the spark efficiency.

Iridium or platinum?

Platinum and iridium spark plugs are the products of more modern technologies, as the use of these metals in the process of electodes manufacturing significantly increases the service life of the element. For example, a platinum spark plug, which is properly selected for the engine, even on bad fuel can live 25-30 thousand miles of run. In the case of iridium, this figure may be about 35-45 thousand.

Platinum and iridium spark plugs are resistant to carbon deposition, resulting in a stable and powerful spark. This allows the engine to burn fuel more efficiently, develop more power, etc.

Advantages of platinum spark plugs:

- Very long service life (up to 60,000 miles), so you don't have to worry about replacing spark plugs;

- The thin electrode produces a large spark and thus improves the quality of the fuel mix ignition;

- the electrodes don't burn out, the gap between them doesn't change;

- the main electrode is supplied with less voltage, which means that it operates for a longer period of time;

- the spark temperature is higher, which allows even the depleted air-fuel mixture to be ignited and can be used in engines with air blowers;

The advantages of iridium spark plugs almost completely duplicate those of platinum spark plugs, plus a few more points:

- even more resistant to oxidation and burnout;

- the strength of iridium is higher than that of other metals;

- the melting point is much higher than that of platinum;

- the iridium spark plug can operate stably over a wide load range;

Some companies (e.g. Japanese spark plug manufacturer DENSO) continue to develop various alloy additives, which enhance operational performance. One of the latest innovations is the iridium-rhodium alloy used in patented products.

Note: Follow the manufacturer's recommendations and consult the operating manual. Always replace the spark plugs before the recommended service interval. Do not wait for a full service cycle to result in blockages in the cylinder head, making removal difficult. In addition, the fuel consumption that occurs during the last 20% of the spark plug life will cost you much more than buying a new set of spark plugs.

The use of high-tech spark plugs not only allows you to forget about the problem of replacement for a long time, but also is one of the factors that will save fuel in the near future and increase the engine life in the long run.

However, in some cases it will be more appropriate to use simple nickel spark plugs: if the engine is worn out, oil will settle on the spark plugs, which means that even expensive spark plugs will not last a long time. Also using poor quality gasoline makes the purchase of expensive spark plugs useless: even on the iridium electrode, carbon residue will form, destabilizing spark plug operation.

Conclusions

Copper (or chromium-nickel) plugs are standard. They are inexpensive and wear out their resource in 15-18 thousand miles. Choosing such a spark plug, you buy a reputable quality product and do not overpay.

Platinum spark plugs (or from other precious metal) are an advanced and improved technology.

The use of platinum in the manufacture of the electrode gives the plug a longer service life.

If the platinum plug meets the required parameters, you will travel with it at least 30 thousand miles. In addition, platinum spark plugs are less susceptible to the formation of soot, which allows the engine to disclose its resource in its full form. In other words, the car will be better to drive.

Iridium spark plugs. Application in manufacturing of iridium spark plugs improves characteristics of a plug in times. Perfect, uninterrupted spark formation allows the engine to work better. The resource of such a spark plug is about 60 000 miles.

So, what spark plug to put in the car? Which spark plugs are better - iridium or platinum? Or, maybe, it is better to choose conventional copper ones? The answer lies on the surface. Iridium and platinum are expensive, but work better. In addition, an extended service life will eventually justify the cost.

Of course, an iridium spark plug is better than a platinum one. If you can afford it, it is better to give preference to iridium. If money isn't so good, then platinum will do just as well as the golden middle. The main thing that should be remembered is that no matter what the spark plug is, if it is picked up incorrectly, it will definitely affect the engine operation and the service life of the plug.